Laser Cutting Machines

Laser cutting is a technology that uses a high-powered laser to precisely cut through various materials. The process involves directing a focused laser beam—typically guided by optics—onto the material, which then melts, burns, vaporizes, or is blown away by a jet of gas. This results in clean, high-quality edges with an excellent surface finish. Fun fact: Industrial laser cutters are not only used for flat-sheet materials but also for cutting structural components and i.e rotary steel rule dies.

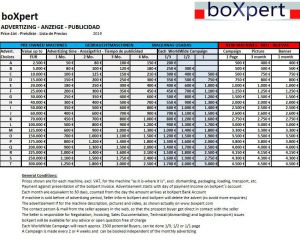

At boXpert, we offer a wide range of laser cutting machines tailored to your specific needs (steel rule dies / cutting formes). You can choose from our selection based on preferences like condition, brand, and availability—making it easy to find the perfect match for your projects.

|

#/page

|

|

(1) Not functioning, need spare parts

(1) Not functioning, need spare parts (3) Running condition, suggest maintenance

(3) Running condition, suggest maintenance (4) Running condition, good

(4) Running condition, good (5) Very good condition, almost newmachine new

(5) Very good condition, almost newmachine new (5) Very good condition, almost newcompletely refurbished

(5) Very good condition, almost newcompletely refurbished